Lately, there has been much discussion regarding the Masela Oil and Gas Working Area Block (WK) development scheme, located in the sea off Maluku. There is debate over which scheme is better between onshore and offshore. This article will discuss in general the comparison between the two schemes.

What is the meaning of onshore and offshore?

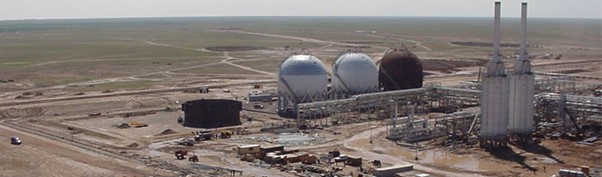

Onshore, translated from English, which means land that approaches the sea or is on land and not at sea1, refers to work related to buildings/structures located on land to the coastline for oil and gas exploration and exploitation activities. Examples of onshore works are onshore refineries and boreholes.

Figure 1 Example of an onshore project

Source: cbi.com

Figure 2 Drilling rig onshore

Source: yabiladi.com

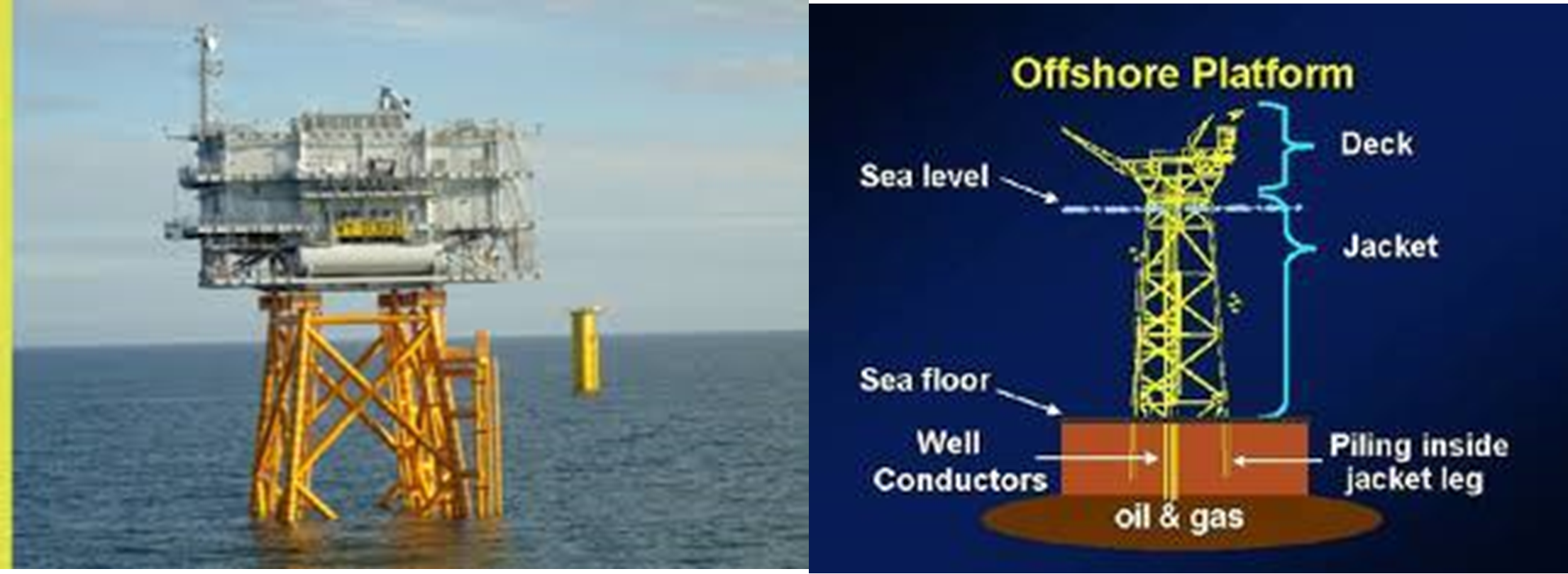

Meanwhile, offshore, which means far from or far from the mainland, is an exploration and exploitation of oil and gas carried out offshore or far from the mainland. In offshore activities, exploration and exploitation are carried out using fixed offshore platforms (jacket, jack-up) or floating (Spar, TLP, FPSO, and others).

Figure 3 Jacket type offshore platform

Source: 2b1stconsulting.com dan fisheries.noaa.gov

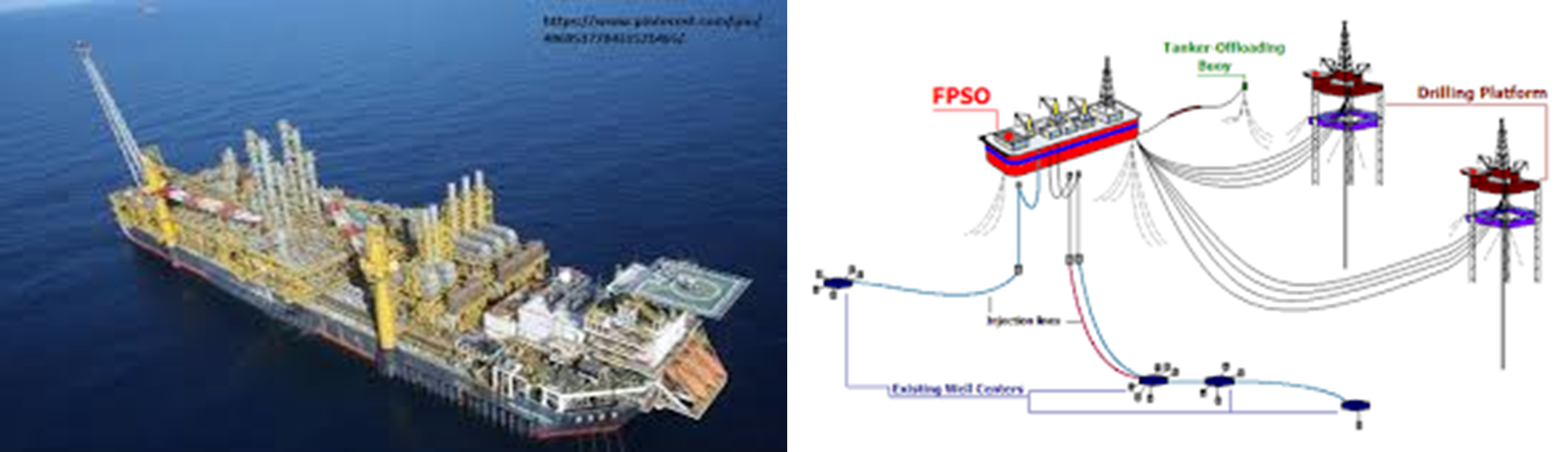

Figure 4 Offshore FPSO type platform

Source: pinterest.com and wikipedia.org

What is the difference between Onshore and Offshore?

Onshore refineries are more accessible to reach than offshore refineries because the location of the refineries themselves can be in the middle of a forest, a mountain peak, in the middle of a desert, even on the edge of a city or village.2 The provisions needed to drill onshore wells are somewhat more accessible than offshore. However, because there has been a lot of exploration and exploitation on land, the chances of finding new oil and gas reserves are smaller than in the oceans.

Besides, the challenges for oil and gas exploration offshore are more significant than onshore. Onshore refinery construction projects must consider the strength of the ground for the foundation and wind loads, while at sea, other aspects need to be taken into account, namely the load arising from the movement of currents and ocean waves. It requires more complex human resources and expertise in designing the refinery.

Moreover, the operational costs required for offshore exploration are more expensive than onshore. From a development perspective, the structural materials used in offshore projects cannot be arbitrary. There need to be considerations related to marine environmental factors such as corrosion and failure caused by marine biota growth. However, the advantage of an offshore rig is that the structure can be moved because it uses floating platforms such as Floating Production Storage and Offloading (FPSO) and Tension Leg Platform (TLP) so that it can be reused for exploration in other locations after it has finished extracting oil and gas from the previous location.

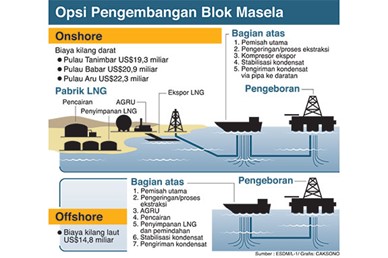

The following is an example of a comparison regarding the above matters: the Masela Oil and Gas Working Area Block in Maluku

.

Figure 4 Offshore FPSO type platform

Source: https://mediaindonesia.com/ekonomi/31471/blok-masela-utamakan-indonesia-timur

It should be noted that the Oil and Gas Working Area Block is located in the sea off Maluku. In the onshore scheme, oil and gas exploitation is carried out at sea using floating offshore platforms for the drilling process. The drilling results are then sent to the mainland using submarine pipes or tanker ships to be further processed into liquefied natural gas (LNG) so that the natural gas from the drilling can be sold and consumed. Apart from the need for offshore drilling facilities, in this scheme, because the wells are located in the high seas, LNG production facilities on land are also needed, and a piping system or sea-to-land transportation. Unlike the offshore scheme, which does not require production facilities on land, LNG production activities can be carried out on platforms or platforms. In the offshore scheme, natural gas from drilling is directly processed into LNG, sent ashore by tanker to be directly sold and consumed. However, the offshore scheme’s use requires a more complex offshore platform because LNG production must be carried out on a platform.

The following are some of the differences in the onshore and offshore schemes3:

| Aspects | Onshore | Offshore |

| Infrastructure | Offshore platforms (drilling), onshore production facilities, transportation systems (pipelines or tankers) | Offshore platforms (drilling and production), transportation systems (tankers) |

| The land acquisition | Unlimited | Limited |

| The Land Conflict | Possible, because the construction of facilities on land is necessary | Low Possibility, due to activities on the high seas |

| Social and Environmental Effect | Possible, due to land activity,, the environment can be polluted | Less social impacts, the environment may be polluted |

| Facilities after the exploitation period is over | Facilities on land are difficult to move, and can be used for LNG production from other wells | The offshore platform can be moved to another exploitation location because it is floating |

| Maintenance | It is easier and cheaper because of access on land | It is more difficult and expensive because it located at the high sea |

Distribution of oil and gas blocks that are managed offshore and onshore

In Indonesia, there have been many oil and gas exploitation activities in onshore and offshore schemes. The following is some data on the distribution of oil and gas blocks in Indonesia4 (SKK Migas report on January 1, 2020).

| No | Working Area | Block/Location | Operator | Commodity | Status |

| 1 | Region I (Sumatra, Riau Islands, dan Natuna Island) | Bangko | Petrochina | Oil and Gas | Onshore |

| 2 | Batanghari | Gregory | Gas | Onshore | |

| 3 | Belida | Sele Raya | Oil and Gas | Onshore | |

| 4 | Bentu | EMP | Gas | Onshore | |

| 5 | Aceh Blok A | Medco | Gas | Onshore | |

| 6 | CPP | BOB – BSP dan Pertamina | Oil | Onshore | |

| 7 | Corridor | CONOCO PHILLIPS | Gas | Onshore | |

| 8 | Duyung | West Natuna | Oil and Gas | Offshore | |

| 9 | Gebang | EMP | Oil and Gas | Onshore and Offshore | |

| 10 | Jabung | Petrochina | Oil and Gas | Onshore | |

| 11 | Jambi-Merang | PHE | Oil and Gas | Onshore | |

| 12 | Kakap | Star Energy | Oil and Gas | Offshore | |

| 13 | Kampar | PHE | Oil | Onshore | |

| 14 | Karang Agung | ODIRA | Oil and Gas | Onshore | |

| 15 | Kisaran | Pacific | Oil and Gas | Onshore | |

| 16 | Korinci Baru | Kalila | Gas | Onshore | |

| 17 | Krueng Mane | ENI | Oil and Gas | Offshore | |

| 18 | Langgak | SPR | Oil | Onshore | |

| 19 | Lemang | Mandala Energy | Oil and Gas | Onshore | |

| 20 | Lematang | Medco | Oil and Gas | Onshore | |

| 21 | Lhokseumawe | Zaratex | Gas | Onshore and Offshore | |

| 22 | Mahato | Texcal | Oil | Onshore | |

| 23 | Selat Malaka | EMP | Oil and Gas | Onshore and Offshore | |

| 24 | Merangin II | Sele Raya | Oil and Gas | Onshore | |

| 25 | Laut Natuna Blok A | Premier | Gas | Offshore | |

| 26 | Sumatra Utara Blok B | PHE | Oil and Gas | Onshore | |

| 27 | Sumatra Utara Offshore | PHE | Oil and Gas | Offshore | |

| 28 | North West Natuna | AWE | Gas | Offshore | |

| 29 | Ogan Komering | PHE | Oil and Gas | Onshore | |

| 30 | Palmerah | Tately | Oil and Gas | Onshore | |

| 31 | Pandan | Tropik | Oil and Gas | Onshore | |

| 32 | Raja and Pendopo | PHE | Oil and Gas | Onshore | |

| 33 | Rimau | Medco | Oil and Gas | Onshore | |

| 34 | Rokan | Chevron | Oil and Gas | Onshore | |

| 35 | Selat Panjang | SGE | Oil and Gas | Onshore | |

| 36 | Sembilang | Mandiri Panca Usaha | Oil and Gas | Onshore | |

| 37 | Siak | PHE | Oil | Onshore | |

| 38 | South Jambi | Jindi | Oil and Gas | Onshore | |

| 39 | South Natuna Sea | Medco | Oil and Gas | Offshore | |

| 40 | South Sumatra | Medco | Oil and Gas | Onshore | |

| 41 | Bukit Barisan Southwest | Rizki | Gas | Onshore | |

| 42 | Tonga | EMP | Oil and Gas | Onshore | |

| 43 | Tungkal | MontD’Or | Oil | Onshore | |

| 44 | Air Komering Barat | Tiarabumi | Oil and Gas | Onshore | |

| 45 | Region II (Jawa dan Kalimantan) | Alas Dara Kemuning | Pertamina | Oil and Gas | Onshore |

| 46 | Bangkanai | Medco | Oil and Gas | Onshore | |

| 47 | Bawean | Camar | Oil | Onshore dan Offshore | |

| 48 | Bengara I | Medco | Oil and Gas | Onshore and Offshore | |

| 49 | Brantas | Minarak | Gas | Onshore | |

| 50 | Bulu | Kris Energy | Gas | Offshore | |

| 51 | Cepu | Exxon Mobil | Oil | Onshore | |

| 52 | Kangean | Kangean Energy | Gas | Onshore and Offshore | |

| 53 | Ketapang | Petronas | Oil | Offshore | |

| 54 | Madura Offshore | Ophir | Gas | Offshore | |

| 55 | Selat Madura | Husky-CNOOC | Oil and Gas | Offshore | |

| 56 | Muriah | Petronas | Gas | Offshore | |

| 57 | Nunukan | PHE | Oil | Offshore | |

| 58 | ONWJ | PHE | Oil and Gas | Offshore | |

| 59 | Pangkah | Saka | Gas | Offshore | |

| 60 | Pasir | Pasir | Oil and Gas | Onshore | |

| 61 | Randugunting | PHE | Gas | Onshore and Offshore | |

| 62 | Sanga-Sanga | PHE | Oil and Gas | Onshore | |

| 63 | Simenggaris | JOB Medco | Oil and Gas | Onshore | |

| 64 | Southeast Sumatra | PHE | Oil and Gas | Offshore | |

| 65 | Tarakan | Medco | Oil and Gas | Onshore | |

| 66 | Tuban | PHE | Oil and Gas | Offshore | |

| 67 | Wailawi | Benuo Taka | Oil and Gas | Onshore | |

| 68 | Wain | Pandawa | Oil and Gas | Onshore | |

| 69 | West Madura Offshore | PHE | Oil and Gas | Offshore | |

| 70 | Region III (East Indonesia) | Berau | BP | Oil and Gas | Offshore |

| 71 | Bontang | StarBorn | Oil | Offshore | |

| 72 | Bula | Kalrez | Oil | Onshore | |

| 73 | East Kalimantan and Attaka | PHKT | Oil and Gas | Onshore and Offshore | |

| 74 | East Sepinggan | ENI | Gas | Offshore | |

| 75 | Ganal | Chevron | Oil and Gas | Offshore | |

| 76 | Kasuri | Genting | Oil and Gas | Onshore dan Offshore | |

| 77 | Kepala Burung | Petrogas | Oil and Gas | Onshore | |

| 78 | Mahakam | PHM | Oil and Gas | Onshore dan Offshore | |

| 79 | Selat Makassar | Chevron | Oil and Gas | Offshore | |

| 80 | Masela | Inpex | Gas | Offshore | |

| 81 | Muara Bakau | ENI | Gas | Offshore | |

| 82 | Muturi | BP | Gas | Onshore dan Offshore | |

| 83 | Rapak | Chevron | Oil and Gas | Offshore | |

| 84 | Salawati | Petrogas | Oil and Gas | Onshore and Offshore | |

| 85 | Sebuku | Pearl | Gas | Onshore and Offshore | |

| 86 | Sengkang | Energy Equity | Gas | Onshore | |

| 87 | Senoro-Toili | JOB Medco | Gas | Onshore and Offshore | |

| 88 | Seram Non Bula | CITIC | Minyak | Offshore | |

| 89 | Tarakan Offshore | Manhattan | Oil and Gas | Offshore | |

| 90 | West Salawati | MontD’Or | Oil and Gas | Onshore and Offshore | |

| 91 | Wiriagar | BP | Gas | Onshore |

By Hadian Bagas Widyawan and Kevin Alief Adityaputra

- Walter, E., 2008. Cambridge advanced learner’s dictionary. Cambridge university press.

- Walter, E., 2008. Cambridge advanced learner’s dictionary. Cambridge university press.

- Annisa Ayu Artanti, 2016. Kelebihan dan Kekurangan Fasilitas Offshore atau Onshore Blok Masela. https://www.medcom.id/ekonomi/energi/1bV0OgaK-kelebihan-dan-kekurangan-fasilitas-offshore-atau-onshore-blok-masela (diakses 02/02/2021)Annisa Ayu Artanti, 2016. Kelebihan dan Kekurangan Fasilitas Offshore atau Onshore Blok Masela. https://www.medcom.id/ekonomi/energi/1bV0OgaK-kelebihan-dan-kekurangan-fasilitas-offshore-atau-onshore-blok-masela (diakses 02/02/2021)

- Badaruddin, M., 2018. Dinamika Industri Migas dan Pertambangan di Indonesia. Jakarta: Jurusan Ilmu Poilitik, Universitas Bakrie